Covid 19 report sees construction productivity improve

This post has already been read 1236 times!

A academic research paper commissioned by Balfour Beatty and carried out by Loughborough University construction sites has found that far from being diminished, productivity may actually have improved.

This research was commissioned to provide a rapid ‘snapshot’ of the impact of COVID-19 on construction. There are opportunities for further work to build on the findings: to improve understanding of the impact of the changes made, what benefits may arise from their adoption long term and what measures might be needed to ensure that new ‘good behaviours’

are retained.

The response to COVID-19 seems to have been rapid and effective on the six projects studied for this research. Site layouts and working practices have seen substantial changes in a short space of time and these changes have been successful and generally well received. There

is emerging evidence of additional benefits to worker effectiveness and productivity and a perception of improved safety and health.

More time is spent planning work tasks; with frontline workers typically deployed in smaller groups than usual and trades working in sequence rather than side by side. This has led to increased worker effectiveness and productivity, and improved housekeeping on most sites.

It has helped to mitigate project challenges arising from other COVID-19 impacts, such as a reduced workforce and problems with material supply. There may well be long term gains from maintaining these ways of working.

There is a perception that general safety and health risk might have been reduced as a consequence of increased planning, fewer workers and improved housekeeping. Changes made to induction processes and to welfare and hygiene arrangements were reported and have the potential to improve the safety, wellbeing and motivation of the workforce if maintained longer term.

At the same time, there have been very high demands on many of the staff involved in managing or re-planning sites and projects, with adverse impacts on wellbeing for some. It is important that relevant employees have time and opportunity to recover and regroup, particularly as a ‘second wave’ of COVID-19 could make further demands.

COVID-19 has led to significant changes to construction work over recent months. There have been suggestions that productivity and ‘normal’ (non-COVID-19) safety and health might have improved as a result of these. The Loughborough team was commissioned to investigate some of the changes made and their impact, and to consider whether their continued adoption post-COVID-19 might offer long term benefits.

Overall, the COVID-19 changes reflect a phenomenal effort by site staff, frontline workers and occupational safety and health professionals. The success of these interventions was underpinned by:

- – Advance planning, so that many sites made changes ahead of government policies and guidance

- – Rapid decision making and action, low bureaucracy, strong teamwork and flexibility

- – Huge site reconfiguration

- – Long hours and very high pressure on many staff1

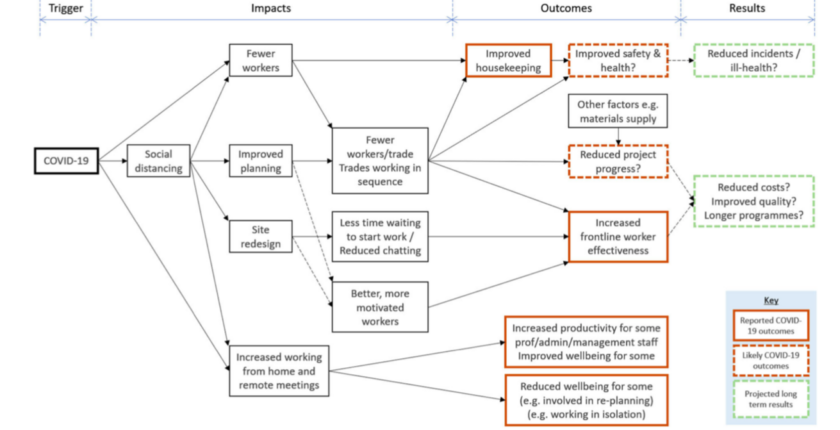

Some of the key impacts, outcomes and potential longer-term results of COVID-led changes are summarised below. Where these are positive, they arise mostly from extending or embedding known good working practices rather than from adopting new methods.

Improved planning, improved productivity, improved tidiness

All five study sites had increased the time spent planning work and tasks. There was a widespread view that planning in this way was beneficial, albeit time consuming: in most cases, it contributed to increased worker effectiveness and improved site tidiness.

The full report of the findings, Covid-19 and construction: Early lessons for a new normal?, states: “Overall project progress i.e. whether, and to what extent, projects had fallen behind the pre-Covid-19 expected programme was variable. It was influenced by a range of factors including having fewer workers on site, difficulty getting materials, and specialist suppliers being closed due to lockdown. Some tasks took longer than usual due to the need for workers to maintain social distancing.

“A range of mitigating measures were put in place. One project introduced a second shift to step up construction whilst still having fewer workers on site at any one time. Other tasks were rescheduled or carried out in different ways: one site used offsite manufacture to reduce the need for workers to be in close proximity, although this increased direct costs.

“Individual or gang productivity/effectiveness was considered to have improved to some extent on all five main sites: i.e. there was higher output per worker, even if total site output was reduced by having fewer workers.

“Factors seen as contributing to this improvement included:

- Better and more detailed task planning

- More space, fewer people, and less overlap of trades in the workplace improves gang/task productivity

- Better planning by workers e.g. preparation of workplaces re tools and materials

- Less double handling of materials

- Fewer people ‘hanging around’ waiting to start work/tasks

- More streamlined worker flow due to workers staggering their start times, reducing the need to queue for site access or changing rooms

- People chatting less (due to distancing, one-way walkways etc), less talking on phones

- On one site there was a perception that those who had returned to site were the more

- motivated workers, the ‘team-players’

- Some workers may also have been enthusiastic and energised at returning to work after furlough.”

The report concludes with some final thoughts:

“The way in which the construction sector has adapted to the challenges of Covid-19 has highlighted its flexibility, resilience, and ability to solve problems. It has enabled several projects to move forward with innovations which might otherwise have taken several years to embed. It has also inspired many to raise their game and has challenged some conventional thinking about the ways in which projects are planned and undertaken.

“There is, however, a high potential for things to drift back towards ‘business as usual’ as Covid-19 related constraints are relaxed and as commercial pressures once again come to the fore. It is strongly recommended that individual companies and projects conduct a ‘lessons learned’ review before long to capture the changes made and ensure that positive changes are captured and embedded.

“It is important that the sector takes full advantage of this uninvited learning opportunity, engaging in wider discussions about the culture and accepted norms of construction and what benefits might accrue from rethinking these.”

Skanska’s Humber Tunnel project was one of the sites studied. Dylan Roberts, Skanska’s health, safety and wellbeing director, said: “Following our work with the Construction Leadership Council on the industry-wide site operating procedures, I felt that we should obtain an independent review of our perception that workforce engagement and planning of work activities had improved. This research is an external verification of the great work done by site staff and provides a positive view of workforce productivity.

“No one could have predicted the impact this pandemic would have on our onsite and remote work delivery, while maintaining optimum safety guidelines and procedures. Covid-19 has shown our industry to be at its most collaborative and innovative when it’s been most needed.”