Timber and brick socks rise as housing sector slows

This post has already been read 199 times!

Brick and timber supplies are largely returning to normal after supplies chains were hit hard in the pandemic and after the crisis due to upsurge in demand.

Bricks have started to be stockpiled after many housing sites have slowed down after Liz Truss’s disastrous mini budget and a rapid hike in intrest rates that followed affected the housing sector instantly.

The Builders Merchants Federation has reported more improvements and balance of product demand and supply, with good availability for most construction products and prices no longer as volatile.

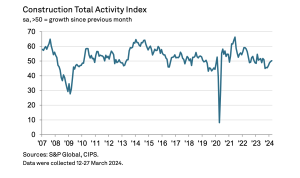

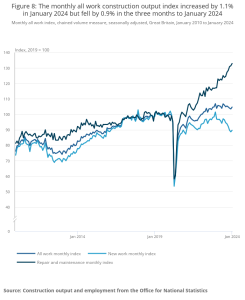

While demand has slowed in recent months, work in every major construction sector, apart from commercial, remains above pre-pandemic levels.

Merchants are now holding large stocks of most grades of timber in the UK and prices are becoming more reasonable as demand slows due to economic pressures exceptions being birch plywood and Siberian larch cladding, which come from Russia, but substitute products are available.

As reported last month, price inflation has largely stabilised with some suppliers deferring price increase as demand slows. Gas prices appear to be easing and many larger energy intensive manufacturers have likely hedged a high proportion of their energy costs for the year ahead. Nonetheless, the impact on manufacturers from high energy costs often takes months to feed through to product prices – especially for energy-intensive products and materials – so the volatility from late 2022 may still be felt into the spring. Inflationary pressures on other costs, especially labour, continue and may well impact prices later in the year.

The Product Availability Group is monitoring potential impacts from the earthquake in Turkey that could disrupt supply chains. While nothing major has been reported to date, Turkey is one of the world’s largest exporters of raw iron bars and Turkish ports are key connections for steel rebar and structural steel global trade. There may be longer term ramifications, for both materials and labour, when rebuilding begins.

CEO of the Builders Merchants Federation,John Newcomb, commented saying that: “Price inflation has largely stabilised with some suppliers deferring price increase as demand slows.

“Gas prices appear to be easing and many larger energy intensive manufacturers have likely hedged a high proportion of their energy costs for the year ahead.

“Nonetheless, the impact on manufacturers from high energy costs often takes months to feed through to product prices – especially for energy-intensive products and materials – so the volatility from late 2022 may still be felt into the spring.

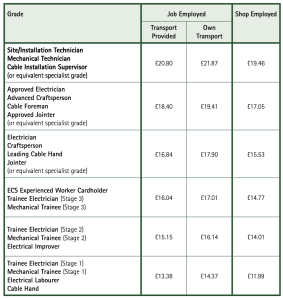

“Inflationary pressures on other costs, especially labour, continue and may well impact prices later in the year.”